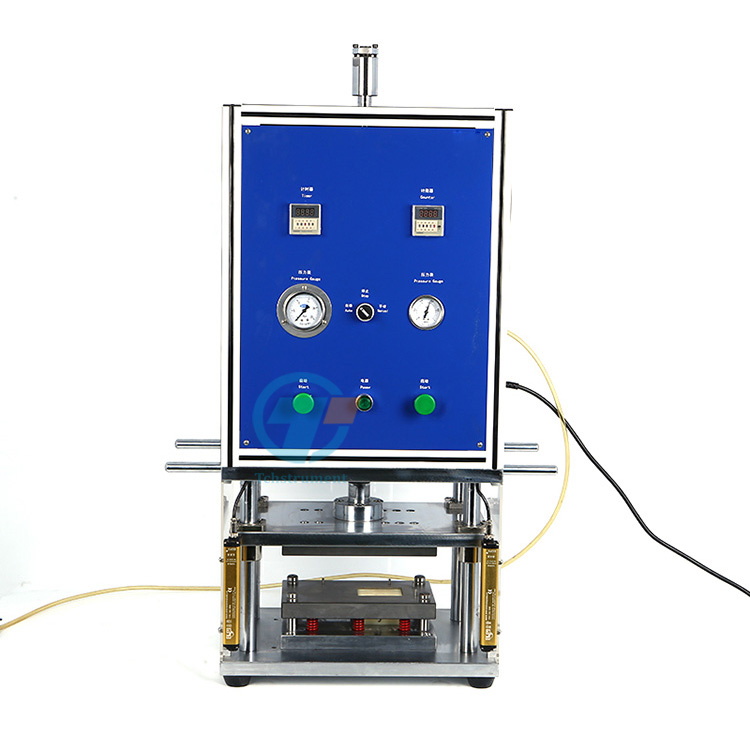

This cup forming machine used in the production line of making pouch cell batteries with two optional size ranges. It is used to prepare polymer cases made of Aluminium Laminated Films.

Features :

1. Guide pillar structure makes smooth move and high accuracy.

2. It is easy and quick to replace die and regulate the punching depth.

3. Accurate design of die makes no crow’s -feet and corner collapse.

4. Light curtain and cover protection make safety use.

5. The die material is imported from Japan and made of high-strength chrome steel and aluminum alloy with surface treated by environmental electroplating and painting.

6. Nice appearance, metal plate use solid geometry design which is well formed.

7. Easy operation, small volume, safe and reliable.

Specification

|

Model |

TCH-PCFM |

|

Source voltage |

AC 220V/110V, 50/60HZ |

|

Power |

100W |

|

Warranty |

Two years limited warranty with lifetime support |

|

Advantages |

1 Structure of guide pin, slide up and down smoothly with high precision 2 Change mould, adjust tensile depth simply, quickly 3 Use screen and casing protection, guarantee safety 4 High strength of chrome steel and aluminum alloy, surface roasts the paint processing through environmental protection electroplating |

|

Suitable aluminum film thickness |

0.1-0.2mm |

|

Suitable aluminum film size |

160*120mm(L*W), customized, with punching depth ≤6mm |

|

Max. Cup Depth to Punch |

Single pit punching depth ≤6mm |

|

Output |

200-400EA/H |

|

Output pressure |

3T |

|

Air source |

0.5-0.7MPa |

|

Mold materials |

S136 Die steel |

|

Dimension(L*W*H) |

460*320*925mm |

|

Weight |

About 130kg |